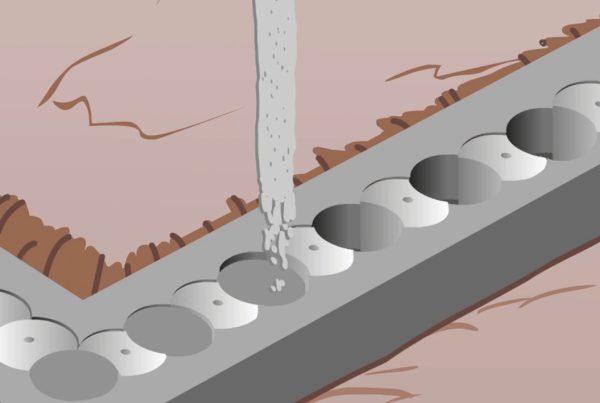

Secant pile walls are a versatile and effective solution for providing earth retention and water control in urban construction projects. These walls are constructed by overlapping concrete piles, creating a continuous barrier that is both strong and impermeable. Over the years, various innovative techniques have been developed to improve the efficiency and effectiveness of secant pile wall construction. This article explores some of these innovative techniques and their applications in modern construction.

Use of High-Performance Concrete

High-performance concrete (HPC) enhances the durability and strength of secant pile walls. HPC is designed to have superior properties such as high compressive strength, low permeability, and excellent resistance to environmental degradation. Incorporating HPC in secant pile walls ensures a longer lifespan and reduced maintenance costs.

Advanced Drilling Techniques

Advanced drilling techniques, such as continuous flight auger (CFA) drilling and rotary drilling, have revolutionized the construction of secant pile walls. These methods allow for precise control over the drilling process, reducing the risk of soil displacement and ensuring accurate alignment of the piles. Additionally, these techniques minimize noise and vibration, making them ideal for urban settings.

Use of Steel Reinforcement

Incorporating steel reinforcement within the concrete piles enhances the structural integrity of secant pile walls. Reinforced secant piles can withstand higher loads and provide better resistance to bending and shear forces. This is particularly important in areas with high seismic activity or heavy construction loads.

Implementation of Real-Time Monitoring Systems

Real-time monitoring systems are increasingly being used in the construction of secant pile walls to ensure quality and safety. These systems involve the use of sensors and data acquisition tools to monitor parameters such as pile alignment, depth, and concrete quality. By providing instant feedback, these systems enable construction teams to make timely adjustments and ensure compliance with design specifications.

Jet Grouting Techniques

Jet grouting is an innovative technique that involves injecting a high-pressure grout mix into the soil around the secant piles. This process improves the strength and impermeability of the soil, enhancing the overall stability of the secant pile wall. Jet grouting is particularly useful in areas with weak or loose soils where traditional methods may be less effective.

Use of Prefabricated Pile Elements

Prefabrication of pile elements off-site can significantly speed up the construction process and improve quality control. Prefabricated piles are manufactured under controlled conditions, ensuring consistent quality and reducing the likelihood of defects. Once transported to the construction site, these piles can be quickly installed, minimizing disruption and project timelines.

Integration with Other Retention Systems

Secant pile walls can be effectively integrated with other earth retention systems, such as ground anchors and soil nails, to provide additional stability. This hybrid approach allows for customized solutions tailored to the specific requirements of the project, ensuring optimal performance and safety.

Conclusion

Innovative techniques in secant pile wall construction have greatly enhanced the efficiency, safety, and durability of these structures. By leveraging high-performance materials, advanced drilling methods, real-time monitoring, and prefabrication, construction professionals can achieve superior results in urban construction projects. As the demand for robust and reliable earth retention solutions continues to grow, these innovations will play a critical role in shaping the future of construction.