Secant pile walls are a type of retaining wall used in construction to provide support to deep excavations, tunnels, and other underground structures. They are created by drilling overlapping holes into the ground and then filling them with reinforced concrete. The resulting wall is strong, durable, and able to withstand high pressure loads.

The construction process for secant pile walls is complex and requires the expertise of experienced engineers and contractors. Here are the general steps involved in building a secant pile wall:

- Site investigation: The first step is to carry out a thorough site investigation to determine the soil and rock conditions. This will help engineers to design the wall and choose the appropriate materials and equipment for the construction process.

- Drilling: The next step is to drill holes into the ground to the required depth. These holes are typically drilled using a drilling rig and a continuous flight auger (CFA) or a Kelly bar. The diameter of the holes will depend on the design of the wall and the soil conditions.

- Reinforcement: Once the holes have been drilled, steel reinforcement cages are lowered into each hole. The reinforcement cages are designed to provide strength and stability to the wall.

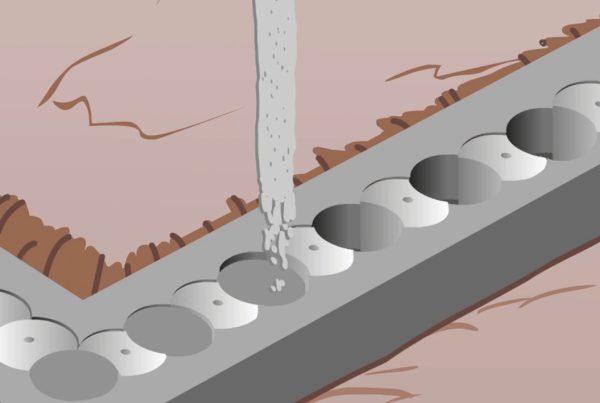

- Concrete pouring: After the reinforcement cages have been installed, concrete is poured into the holes using a concrete pump. The concrete is typically placed in two stages: first, the primary concrete is poured to form the main body of the wall, and then the secondary concrete is poured to form the interlocking segments.

- Interlocking: As the secondary concrete is poured, steel reinforcement bars are inserted into the primary concrete to form interlocking segments. This process creates a continuous wall with no gaps, providing maximum strength and stability.

- Finishing: Once the concrete has set, the wall is finished by trimming the interlocking segments and smoothing the surface. The wall can also be treated with a waterproofing membrane to prevent water seepage.

- Testing: Finally, the wall is tested to ensure that it meets the required strength and stability standards. This is typically done by carrying out load tests and measuring the wall’s deflection and settlement.

In conclusion, constructing a secant pile wall is a complex and specialized process that requires careful planning, design, and execution. It is important to work with experienced engineers and contractors who have a deep understanding of the soil and rock conditions, as well as the appropriate equipment and materials required for the job. By following these steps, a strong, durable, and reliable secant pile wall can be constructed to provide support for underground structures.